Multiwall Polycarbonate Skylights

Multiwall Polycarbonate Skylights

If you’re looking for a solution that is both energy-efficient and impact-resistant, polycarbonate multiwall panels can create amazing, durable multiwall skylights. The multiple layers of sheeting contain air between them, allowing for more effective thermal insulation.

Because they’re made with polycarbonate, multiwall panels are nearly indestructible — while also being lightweight and affordable. Polycarbonate sheets come in a variety of thickness sizes to accommodate different styles of multiwall skylights.

Great for both residential and commercial purposes, some of the most common applications for multiwall skylights include greenhouses, roofs, patios, walkways, sidewalls, sunrooms, swimming areas, stadiums, shopping centers and more. Simply put, polycarbonate multiwall panels are a great way to let the light in, but keep the heat out. To learn more about multiwall skylights, get in touch with our team today!

Product Features

Our skylights are built with a tough aluminum frame exterior providing extra strength to the unit. Built with the customer in mind our frame includes condensation gutters around the interior perimeter and weep holes at every corner allowing your skylight to breathe and whisk away condensation. We thoroughly believe quality control starts at the ground up, with that principle in mind we meticulously inspect each unit for blemishes before it gets our stamp of approval.

We can cater to any job. If you need more than the standard unit fall protection and windstorm approved skylights are a call away.

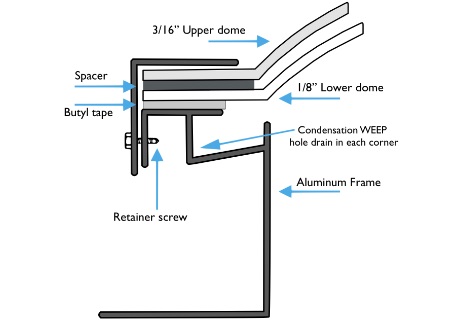

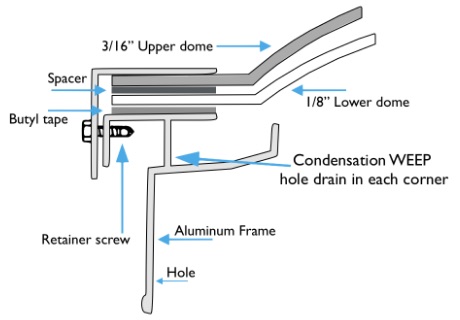

Built in the USA! .078” thick 6063 T-5 aluminum frames support each skylight. Our double dome units are produced with a minimum of 3/16ths clear acrylic on the outer dome and a 1/8th” lens for the inner.

Acrylic also commonly known as plexiglass has been the go-to material for skylight production since the beginning. Acrylic offers strengths up to 50 times stronger than glass at a fraction of the weight. If you need more impact resistance, we have rubberized acrylic, known as modified acrylic, and polycarbonate options available.

Self-Flashing Dome Skylight

Factory assembled skylight with a .078” thick 6063 T-5 aluminum curb frame, with a 4.5” height and 3” nailing flange, and a .062” thick extruded aluminum retainer with stainless steel fasteners attaching the two. The self-flashing frame shall have an integral condensation gutter with weep holes (one each corner) to carry moisture to the outside. All corners are mitered and heliarc welded. Glazing shall be thermal formed domes of acrylic or polycarbonate (your choice of color).

Factory assembled skylight with a .078 thick 6063 T-5 aluminum curb frame and a .062 thick extruded aluminum retainer with stainless steel fasteners attaching the two. Curb Frame shall have an integral condensation gutter with weep holes (one each corner) to carry moisture to the outside. All corners are mitered and heliarc welded. Glazing shall be thermal formed domes of acrylic or polycarbonate (your choice of color).

Product Options

Several materials can be used to create the perfect skylight for each scenario. Our skylights come with a variety of options. Traditional units can be produced to include fall protection as well as heat blocker screens. In order from least impact resistance to the greatest we produce acrylic, impact modified, and polycarbonate units.

Similar Products

Even though our framing may be the same, our skylights can be made in numerous different sizes colors and shapes. Marco Skylights can custom tailor any unit production to fit the needs of your project.